Condition-Based Maintenance.

Reimagined for Modern Engineering Operations.

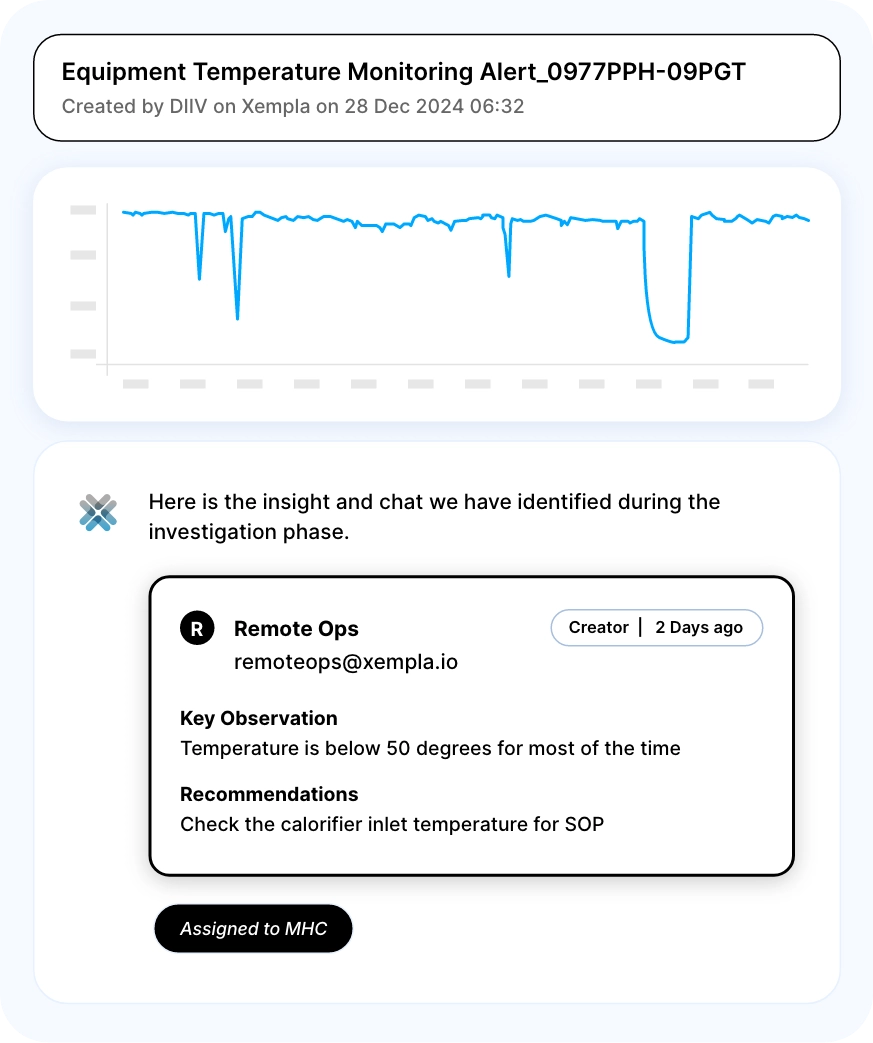

Xempla identifies and prioritizes critical issues based on real-time asset conditions, runs the triaging process autonomously, and recommends precise maintenance actions to enhance asset performance and reliability.

Still Running CBM Like They Did In The 90s?

Current CBM strategies are riddled with inefficiencies and demand a time and resource-intensive model that doesn’t cut it anymore. Instead of enabling proactive maintenance, they slow teams down, expose asset reliability gaps, and limit scalability.

Time-Consuming Manual Triaging

Engineers manually review and prioritize alerts, increasing the likelihood of errors, causing delays in critical issue resolution, and losing valuable time that could be directed to more strategic initiatives.

Siloed Data & Insufficient Insights

Limited contextual insights and fragmented data make decisions unreliable and reactive, often resulting in misdiagnosed issues, incorrect work orders, and inefficient maintenance execution.

High Cost & Limited Scale

As asset portfolios grow, reliance on manual processes makes it impossible to scale operations without overwhelming existing teams or significantly increasing costs and human resources.

Leverage Agentic AI-driven Automation to Deliver the Most Effective CBM Strategy

Xempla combines the best of Agentic AI and advanced automation to help you run the most efficient and optimized condition-based maintenance strategy with minimal engineering supervision.

The most critical issues — ranked, triaged, and ready for analysis

Sound engineering decisions in minutes — with expert system support

Improved collaboration and faster execution of corrective actions

The impact of maintenance programs — automated and documented for you

THE XEMPLA EDGE

Unlock the Assured Pathway to Bigger and Better Maintenance Outcomes

Xempla transforms traditional CBM into an intelligent, automated, and AI-driven process that improves asset reliability, enhances resource efficiency, and optimizes maintenance operations at scale.

Autonomous Maintenance

Xempla’s AI-driven autonomous ecosystem enables a seamless, self-operating maintenance workflow that maximizes operational efficiency with minimal human intervention.

Enhanced Decision-Making

AI empowers engineers with real-time insights and context for root cause analysis, with intelligent recommendations enabling faster, more accurate decisions that drive better corrective actions.

Improved Asset Reliability

By sidelining one-off events and prioritizing critical issues, Xempla ensures high-impact opportunities are addressed effectively, reducing downtime, and improving asset reliability and lifespan.

Standardized Service Delivery

Ensure each engineer, regardless of knowledge and skill level, follows a standardized process to deliver consistent service quality across multi-site operations and customer satisfaction.

Scalability Without Limits

AI eliminates manual bottlenecks and reduces dependence on individual expertise, allowing you to scale operations effectively while maintaining organizational capacity and competitiveness.

Human Resource Efficiency

With human oversight and physical interventions minimized, engineers and maintenance teams can focus on high-value activities, improving productivity without increasing headcount.

JOIN THE CLUB

Drive World-Class Results.

Just Like Some of Our Leading Customers.

Real results, real impact. Top FM & Engineering Service Companies trust Xempla to deliver the goods—consistently.