Smart Automations and Prescriptive Insights for Enhanced Predictive Maintenance

Xempla analyzes live asset data and extracts critical context from past maintenance activities to generate precise prescriptive insights and recommendations — with smart automations helping you prioritize and execute highly targeted interventions in advance.

Modern Engineering Teams Deserve a Better Approach to Predictive Maintenance

Current predictive maintenance solutions are rigid and work well for manual, resource-intensive strategies that are no longer sustainable. Instead of driving predictability and proactive response, they slow teams down, expose asset reliability gaps, and limit scalability.

Static & Inadaptive Models

Traditional rule-based platforms lack adaptability, failing to evolve over time with new operational data and requiring experts to manually configure settings when asset conditions change.

Complex & Siloed Operations

Incumbent solution providers want you to operate within their own ecosystem, offering less flexibility and integrations with your existing tools and preventing a unified view of your assets.

Poor Data Quality & Context

Lack of mission-critical context and data quality concerns make insights unreliable and reactive, often resulting in false predictions, incorrect work orders, and inefficient maintenance scheduling.

Low System Intelligence

Despite offering predictive insights, these systems fail to guide engineers through complex decision-making — resulting in inefficiencies, delayed responses, and suboptimal asset performance outcomes.

Manual-Heavy Maintenance

Most predictive maintenance tools are limited to triggering alerts and weak at automating workflows. Engineers still spend excessive time on manual triaging, reporting, and root cause analysis.

High Cost & Limited Scale

As asset portfolios grow, reliance on manual processes makes it impossible to scale operations without overwhelming existing teams or significantly increasing costs and human resources.

Let AI Do The Heavy Lifting And Automate Critical Workflows for Truly Predictive Maintenance

Xempla combines AI-driven analytics, asset failure assessments, and automated workflows to help you run a more effective, intelligent, and autonomous predictive maintenance strategy with minimal human supervision and maximum impact.

Flags potential failures with 24/7 monitoring and fault detection diagnostics

Xempla monitors your assets round the clock, with multiple fault detection and diagnostics workflows running in the background to analyze live conditional data (pressure, temperature, vibration, etc.) through seamless integrations with your existing tools. Unlike conventional systems, Xempla flags potential issues of a more critical and recurring nature, minimizing false alarms and distractions caused by one-off events.

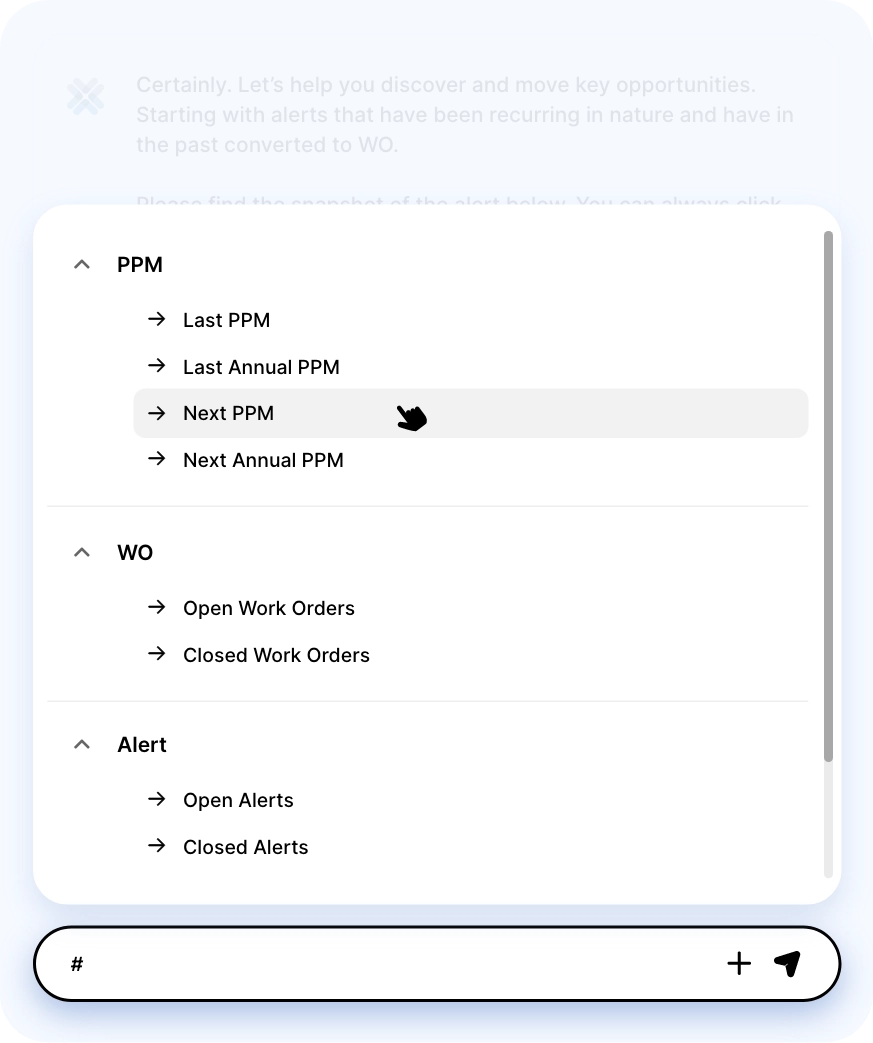

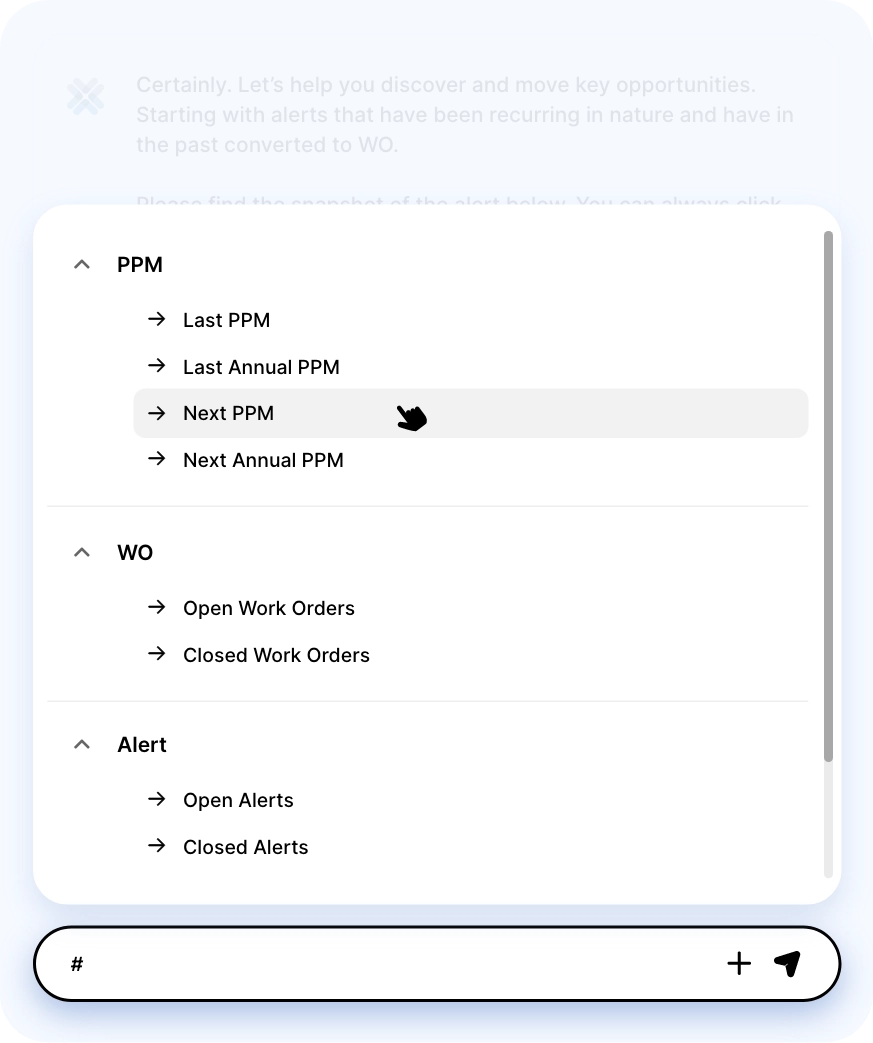

Pulls data and context from past maintenance activities for holistic analysis

Whenever a potential issue is flagged, Xempla doesn’t just look at that occurrence in isolation — it also analyzes past events, patterns, and any simultaneous anomalies happening across your systems. It automatically references recent maintenance logs and service histories to ensure recommended actions consider any recently replaced or serviced parts — preventing unnecessary repeat visits and wasted labour.

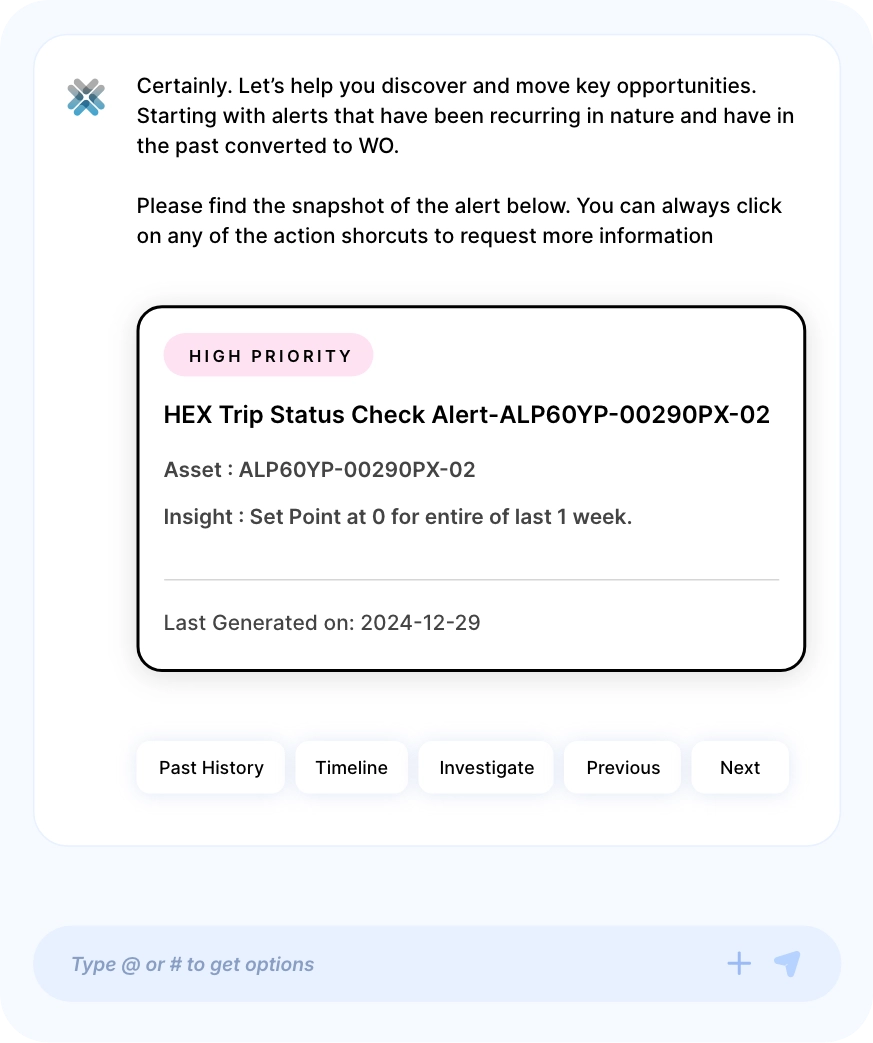

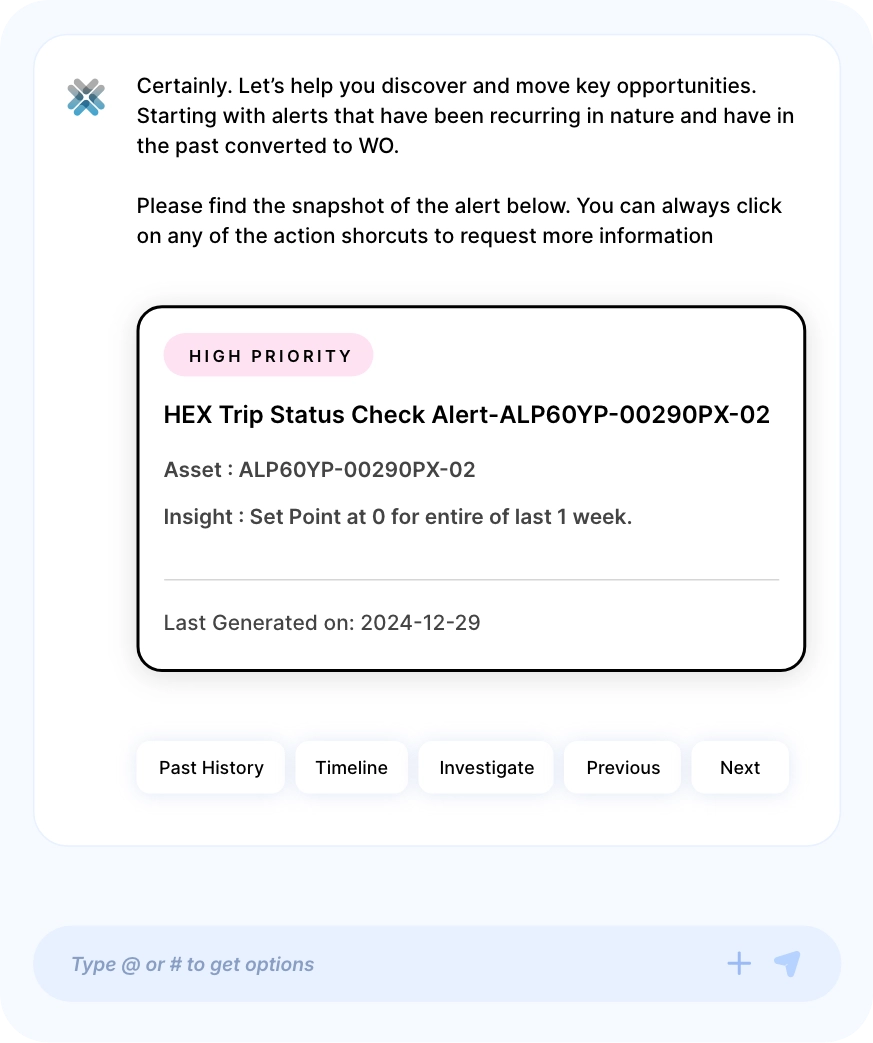

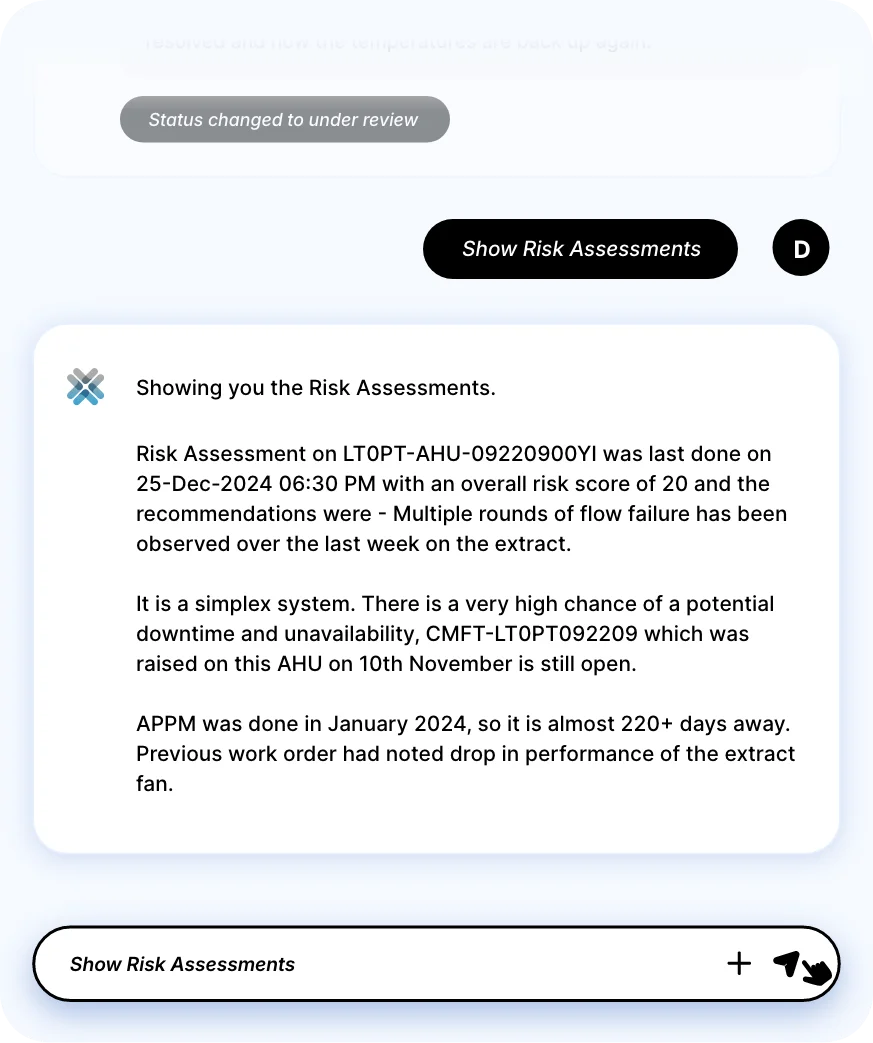

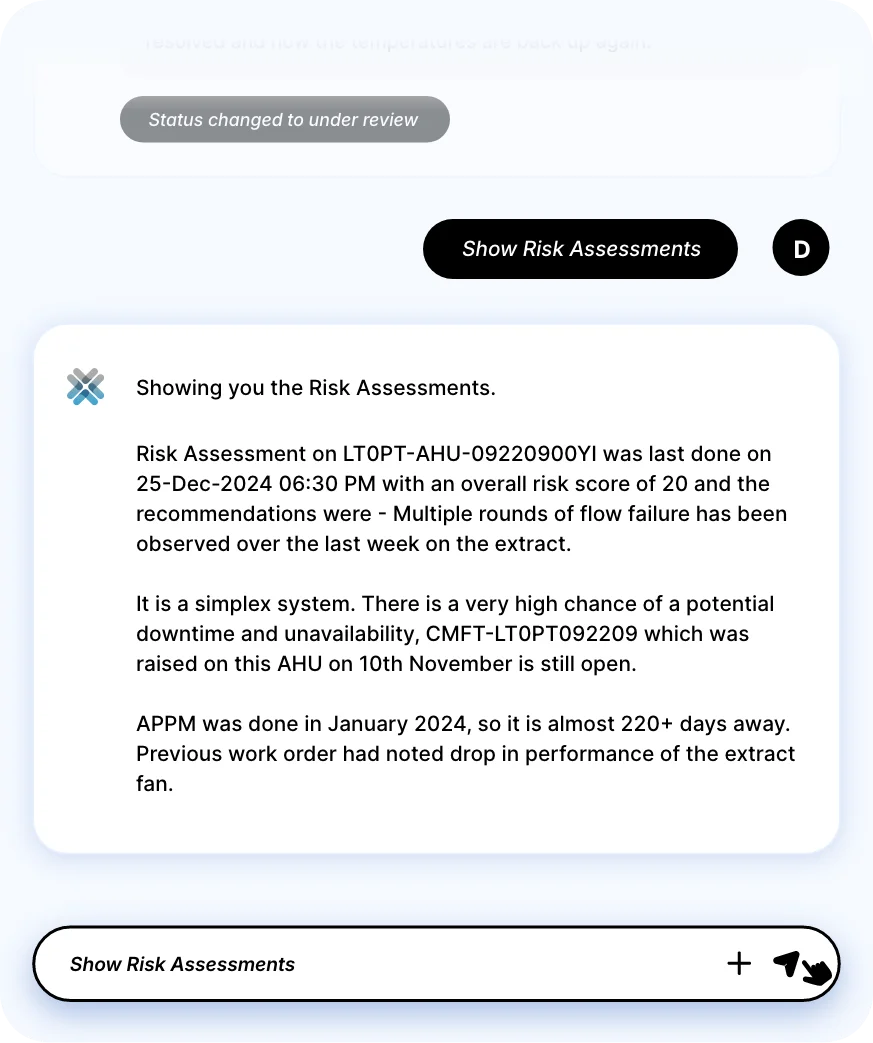

Performs risk assessment and go/no-go scoring for efficient prioritization

Based on real-time data and historical insights, Xempla calculates a go/no-go score, indicating whether the asset is at immediate risk of failure or can safely continue operating. This scoring mechanism helps you prioritize which issues deserve immediate attention based on factors like severity, impact, recency, and frequency (and have a higher chance of converting to work orders) vs those that can be scheduled for later.

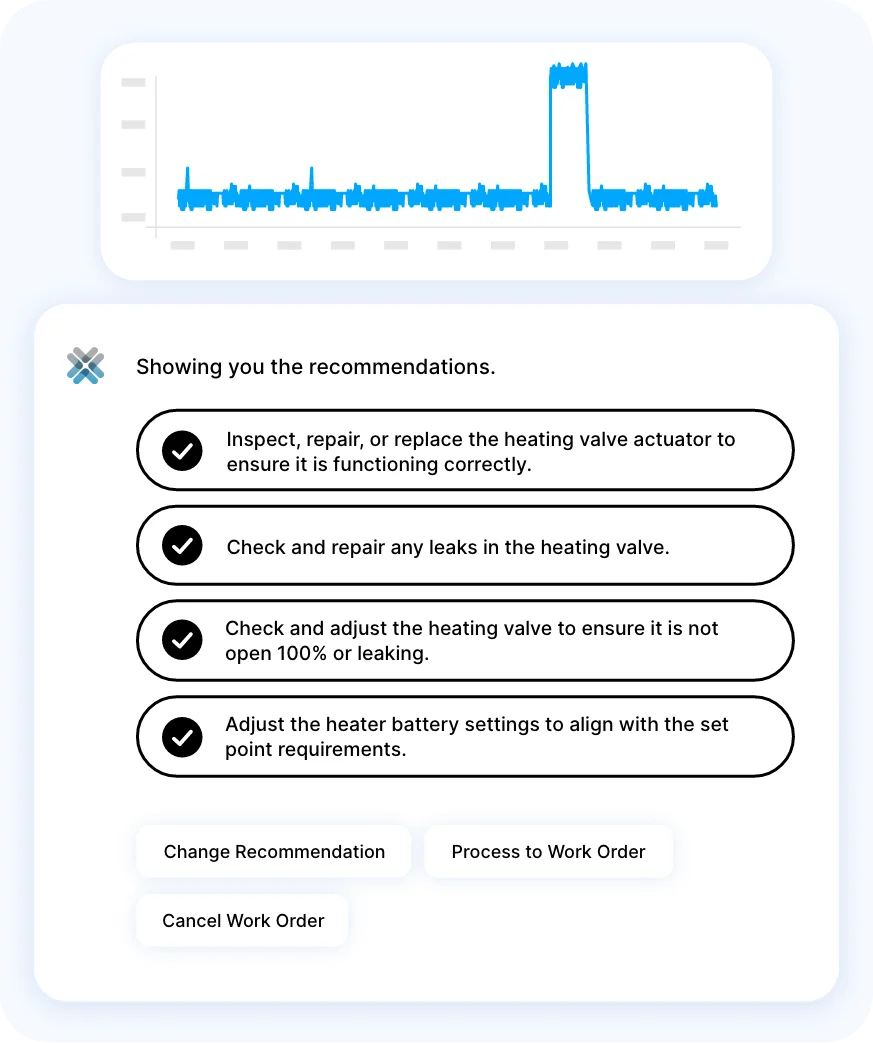

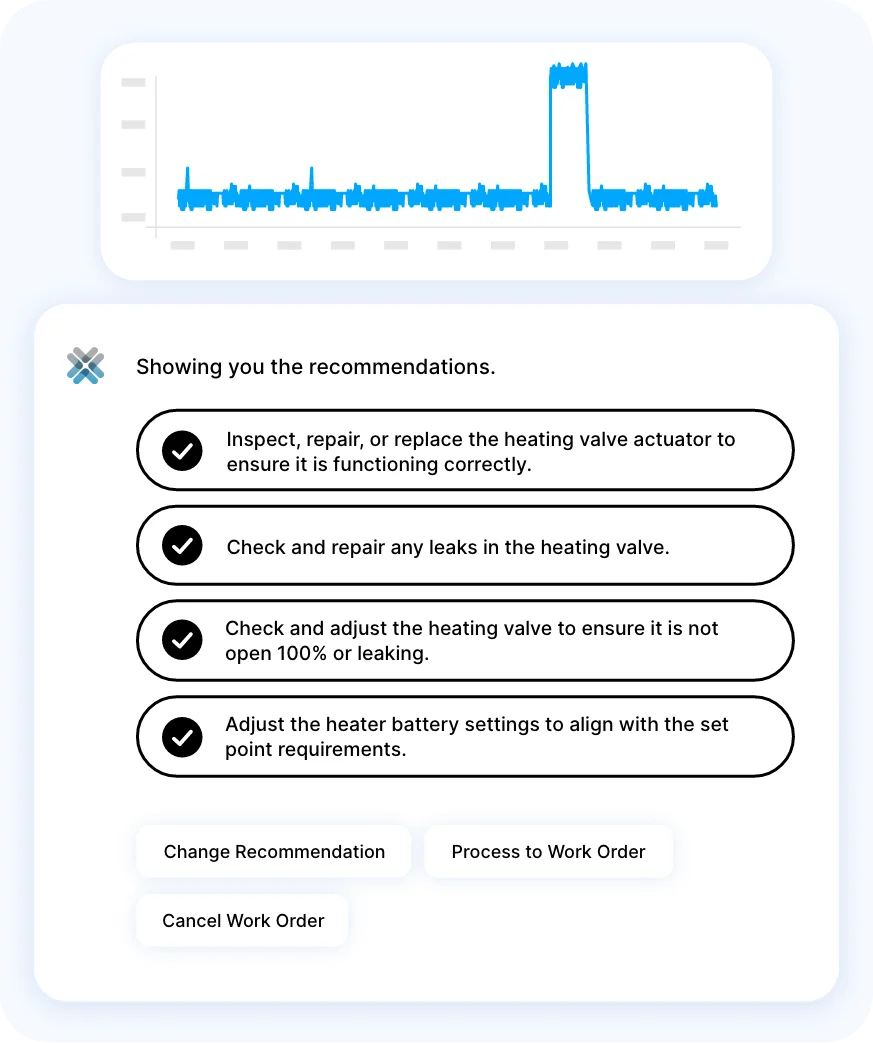

Automates work orders with clear insights and recommendations for technicians

When an asset’s score indicates a high risk of failure, Xempla automatically creates a corrective work order. It provides clear, data-backed recommendations and enables engineers to add supporting notes for technicians on what parts to inspect, repair, or replace — eliminating guesswork and minimizing unplanned downtime. Based on interactions with engineers, Xempla generates increasingly specific and accurate recommendations over time.

More Than Just Predictive Maintenance —

Your Pathway to a Whole New Standard of Efficiency

Xempla goes beyond conventional definitions of predictive maintenance with intelligent insights and automations guiding your team’s efforts towards better business outcomes and offering a more complete solution to modern maintenance challenges at scale.

Autonomous Maintenance

Xempla’s AI-driven approach combined with smart automations enables a seamless, self-operating maintenance workflow that maximizes operational efficiency with minimal human intervention.

Enhanced Decision-Making

Xempla empowers engineers with real-time insights, historical context, and intelligent recommendations — enabling faster, more accurate decisions that drive better corrective actions.

Improved Asset Reliability

By sidelining one-off events, Xempla ensures high-impact opportunities are addressed effectively, reducing downtime, increasing cost savings, and improving asset reliability and lifespan.

Standardized Service Delivery

Ensure each engineer, regardless of knowledge and skill level, follows a standardized process to deliver consistent service quality across multi-site operations and customer satisfaction.

Scalability Without Limits

AI eliminates manual bottlenecks and reduces dependence on individual expertise, allowing you to scale operations effectively while maintaining organizational capacity and competitiveness.

Human Resource Optimization

With human oversight and physical interventions minimized, engineers and maintenance teams can focus on high-value activities, improving productivity without increasing headcount.

JOIN THE CLUB

Drive World-Class Results.

Just Like Some of Our Leading Customers.

Real results, real impact. Top FM & Engineering Service Companies trust Xempla to deliver the goods—consistently.

Elevate Your Predictive Maintenance Strategy With Smart Automations and Prescriptive Insights

Frequently Asked Questions

Xempla’s Agent enables predictive maintenance by leveraging data-driven predictive models to anticipate issues in advance. It can analyze historical and real-time data in seconds and present intelligent insights about an asset’s performance trends, frequency of failures, and work order details, helping engineers schedule maintenance activities based on the likelihood and estimated time of asset failure.

Unlike conventional predictive maintenance software that stops at data collection and alerts, Xempla’s AI Agent automates the full decision-making workflow. It goes several steps further by automatically recommending — and even executing — optimal maintenance actions. It eliminates manual analysis, provides context-aware insights, assigns risk scores for issues, and enables remote teams to make better decisions and act faster — boosting efficiency, reliability, and engineering productivity.

Yes, the Agent is compatible with most CMMS software. By integrating with your existing maintenance management system, the Agent can provide context around schedules, current activities, assessments, and more to arm engineers with the information they need without having to leave the interface or change the momentum of the investigation. It can then automate work order generation and tracking, and automatically update its status and details on your CMMS. We already have integrations with a host of BMS, IoT, CMMS, and CAFM systems widely used in the industry.

While the Xempla Asset Performance Management platform runs in the background, the Agent identifies high-priority discoveries and provides contextualized information in one place to help engineers make go / no-go decisions on work orders faster. Once work orders have been closed, the agent automates impact verification to ensure asset performance issues have been addressed and feeds it back into the platform’s feedback loop. Together, they drive continuous optimization and performance improvements across asset lifecycles.

The Agent enhances maintenance efficiency by automating the initial triaging of tickets, prioritizing high-impact issues, and enabling engineers to focus their efforts on critical tasks. The automation process reduces manual work, allowing engineers to handle more tickets per day. This leads to significant cost savings and better resource allocation across teams, improving overall maintenance efficiency and reducing maintenance costs.